Use Cases.

The following examples of Use Cases demonstrate a few of the many ways that ACTIS ERP software can help you manage your business and your portfolio.

Asset

Management.

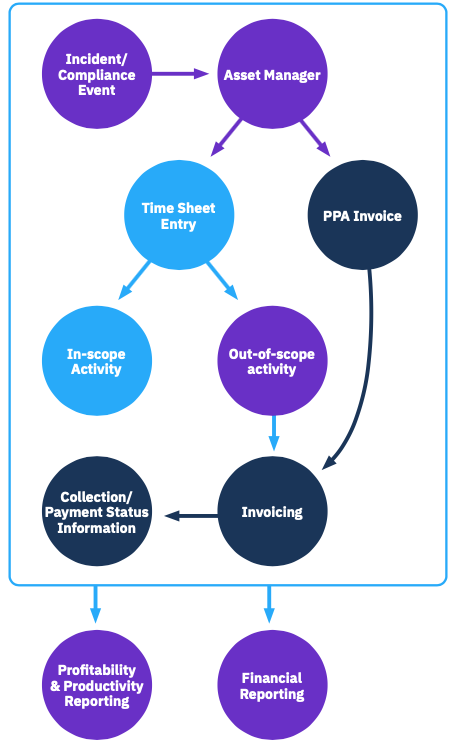

Such activities can include the PPA Invoice generation or various other activities.

The time spent to manage an incident is tracked in a Time Sheet calendar and classified as Out-Of Scope or In-Scope activity.

Out-Of-Scope Activities are market for billing.

Accountants track the status of the Invoice generated (Paid, Pending, Cancelled etc.) in their accounting system.

Via an integration with the Accounting system your organization is already using, the Asset Manager and Management are always aware of the status of each invoice without the need to ask the accountant as this is constantly synced.

Based on this data various reports can be generated with the click of a button, for example:

- Contract Profitability

- Team Productivity

- Financial Reporting

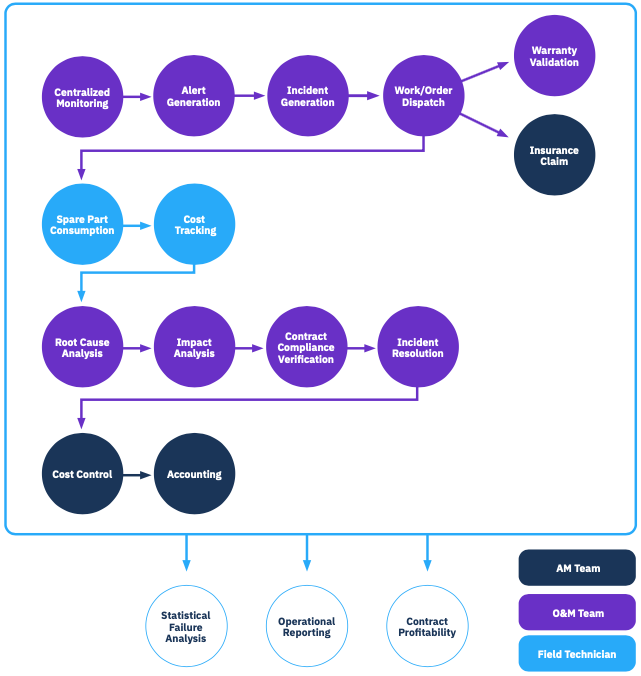

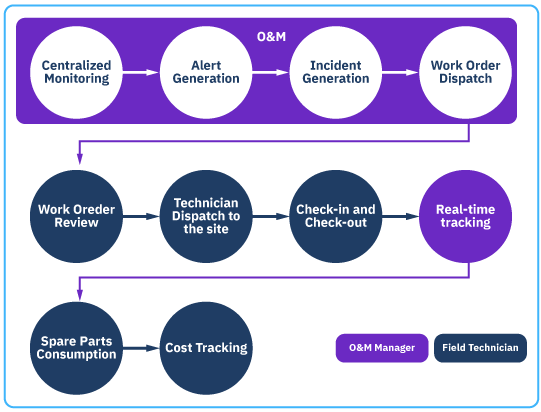

O&M.

Alerts are generated out of ACTIS ERP software based on the configuration in the system.

Upon receipt of an alert and its verification from the monitoring dashboard an incident is created in the system and remains open until its final resolution.

Existence of any valid warranties are checked or an insurance claim in initiated (for example in case of a Force Majeure event).

When needed, field technicians or subcontractors can be dispatched to the site.

Field personnel tracks the spare parts used and the costs incurred for each site visit.

The O&M team receives all information from the field and before finally closing the incident, tracks the root cause of the failure, the impact of the failure to the operation of the asset (downtime, KWh lost, money lost etc.) and associates the incident with a valid service contract in order to be able to track compliance with contractual obligations.

Upon resolution of the incident, Asset Managers are able to track and validate costs and approve where applicable to billing or paying.

From the information collected throughout this process numerous Technical, Operational or Financial Reports can be generated. e.g.:

- Statistical Failure analysis (for example KWh

lost vs root cause or equipment) - Monthly operational reporting including the

overall performance of the asset and the corrective and preventative maintenance incidents throughout the month - Contract profitability based on revenues generated from the contract and costs insured

Fleet

Management.

A work order is dispatched from the platform by the O&M manager and assigned to the field personnel.

The work order sent automatically from the system is reviewed by the technician in the mobile app. The app is intuitive, easy to use with online and offline (where there is no coverage) functionality.

The technician checks the details of the work order and looks up the location of the relevant site on the app map.

The field engineer is dispatched to the specific site following the GPS guidance in the mobile app.

Once ready to work. the technician checks-in on the site and commences the work order execution.

The mobile app enables the field personnel to add comments, notes, upload relevant pictures, fill in the checklists, and set the status of the work order.

When the work order is completed, the technician checks-out in the mobile app.

The real-time position of the field engineer, the route, the check-in and check-out times are tracked in the system and accessible to the O&M manager. The app automatically calculates the work time, travel time and distance realized by the field personnel, and estimates the time of technician arrival to the next site.

The field engineer tracks the spare parts used and the costs incurred for the site visit. All the information is available to the O&M manager in the ACTIS ERP software.

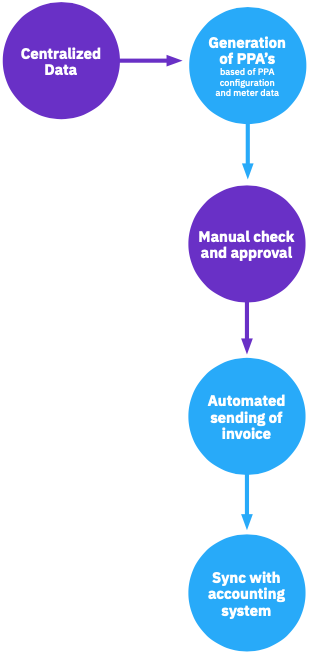

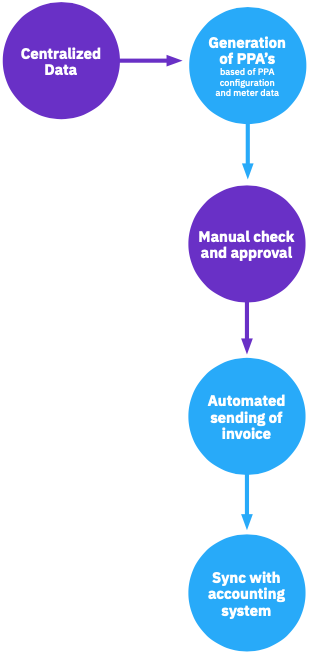

PPA

Billing.

The PPA is configured, consequently, PPA pricing is defined for each Subscriber and Offtaker. The PPA configuration also contains a split of % for the measured kWh per Subscriber and Offtaker.

ACTIS ERP synchronizes with accounting systems, such as QuickBooks and SAP, to avoid double handling and errors. This way software frees up valuable time and resources for managers to concentrate on more value-added activities.

The software can automatically track the status of invoices, notifying the team and accountants if the invoice is paid or not paid.

ACTIS ERP provides the functionality of workflow approvals and user error prevention. ensuring no mistakes occur during the PPA billing process. It also offers additional aggregated reports making the validation and approval of invoices very easy before releasing to the customer.

Invoices can be customized according to client expectations. including adding personalized templates and logos.

Accurate. hassle-free and reliable invoices are sent automatically from ACTIS ERP software.